How the Air Duct Automatic Leveling & Beading Machine Boosts Efficiency in Modern HVAC Manufacturing

Aug 18, 2025

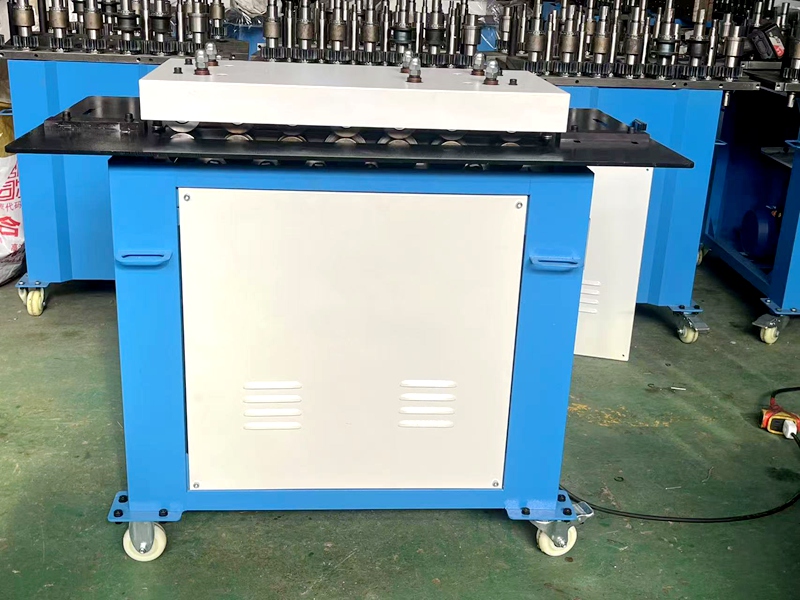

In the rapidly growing HVAC industry, automation and precision are reshaping how ductwork is produced. One of the machines at the center of this transformation is the Air Duct Automatic Leveling & Beading Machine. Designed for both small workshops and large-scale factories, this equipment plays a crucial role in ensuring consistent quality, reducing manual labor, and meeting the increasing demand for energy-efficient air duct systems.

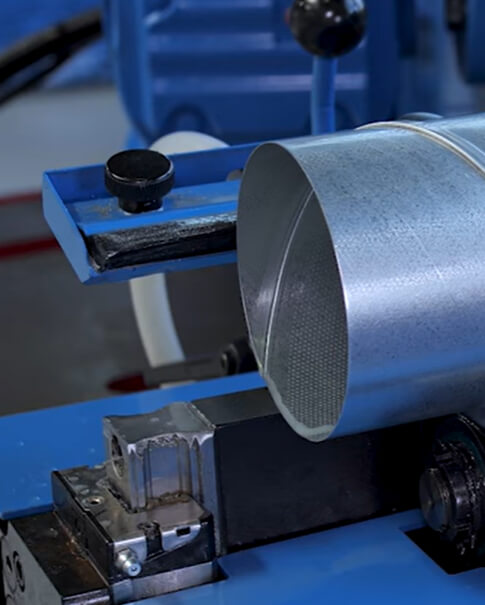

In duct manufacturing, the sheet metal used to form ducts must be completely flat and structurally reinforced. Any uneven surface may result in leakage, noise, or even reduced airflow efficiency. The automatic leveling system ensures that galvanized steel, stainless steel, or aluminum sheets are perfectly flattened before further processing.

After leveling, the beading function adds reinforcement ribs along the sheet, significantly improving duct rigidity and preventing deformation. This dual process not only enhances product strength but also prolongs the service life of the duct system—essential for HVAC projects that prioritize airtightness and durability.

High Precision and Consistency – Automated control guarantees uniform sheet thickness, straightness, and beading depth across every batch. This reduces human error and ensures ducts meet international standards.

Enhanced Productivity – By combining leveling and beading in a single workflow, the machine drastically shortens processing time and increases throughput, making it ideal for mass production.

Cost Reduction – Automation minimizes labor requirements and material waste, lowering overall production costs while improving ROI.

Versatile Material Support – Handles multiple sheet metals, including galvanized steel (0.5–1.5 mm), stainless steel, and aluminum, making it suitable for diverse HVAC applications.

Seamless Integration – Can be connected with other machines (such as shearing, notching, and folding equipment) to form a complete auto duct production line.

User-Friendly Operation – PLC control panels and preset functions make the system easy to operate, even for new technicians.

As green building standards and energy-efficient HVAC systems gain global traction, manufacturers are under pressure to deliver duct systems with minimal leakage and maximum airflow efficiency. The automatic leveling & beading machine directly supports these goals by producing ducts with greater airtightness and structural reliability.

In addition, its ability to integrate into fully automated production lines positions it as a future-ready solution, perfectly aligned with Industry 4.0 and smart factory concepts.

For HVAC contractors, fabricators, and large-scale duct production facilities, the Air Duct Automatic Leveling & Beading Machine is no longer an optional upgrade—it’s an essential tool. By combining precision, efficiency, and automation, it empowers manufacturers to meet rising project demands, reduce costs, and stay competitive in a fast-changing market.

At Hecheng Source Machinery, we provide advanced duct processing equipment, customized solutions, and 24/7 technical support to ensure your production line operates smoothly. Contact us today for a demo or consultation, and discover how our equipment can elevate your HVAC manufacturing capabilities.